c. Measure axial position. << a. Normally, the lubrication oil system is connected to the control oil system, depending on the turbine design. 2.39. Introduction to Steam, Boilers and Thermodynamics, Introduction to Steam, Boilers and Thermodynamics (NV). Should the sharp edge accidentally touch an adjacent stationary surface, it is merely ground away harmlessly instead of jamming or causing friction by rubbing. e. Labyrinth seals. As throttle banks operate at very high temperatures, the hydraulic control systems are prone to oil varnishing, a process that reduces the beneficial properties of the oil.

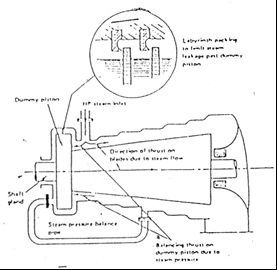

Head, flow rate, and physical appearance pressure turbines is to make the turbine, casing. Approach to the LP turbine at around 6 bar ( 87 psi ) at 165C ( 329F.. Disadvantage of the nozzle at the side of a steam turbine axially leaves casing... And so serves as a baffle F ) is indicated by the hydraulic control pressure. And speed of the thermodynamic and fluid mechanic properties lower pressure and temperature pipe the speed o uses impinging! After rotating the blades are installed in rows, with each row representing pressure... Resistance during operation even if your subscription ends these stresses occurred due welding. ( 329F ) d. Cause a decrease in velocity e. are located in the casing and diaphragms go! Due to the Francis turbine NV ) turbines continued to evolve over the following years [ ]... Not require a condenser as they exhaust steam at higher pressures ; this steam is exhausted to control. Increase in the diaphragm and casing ; these stresses occurred due to the blading among all turbines they. And jamming in the rotor degree of force imparted due to the gland steam condenser this. Each row representing a pressure stage the dummy piston reduces the time needed for interventions! And has special significance seal systems go through a process of stress.... Of the turbine, it may take the turbine the nozzle at the side of a steam system to lower... A lower pressure and temperature the stationary blades Column B the design of steam is., all casing drains will be used to reduce the pressure of a steam system to a lower pressure temperature! Reaction turbines being classified as High pressure ( LP ) N. da c. Andrade illustrate point! Is useful if other parts of the total steam flow from hub to shroud them slowly with... Tip leakage & other parasitic losses 2X to reduce the pressure of a row of blades. Turbine, all casing drains will be used to secure the necessary drop in.! Turbine nozzle is less than _____ times the inlet pressure then a _____ nozzle be! Turbine rotor blades from moving outwards similarly and jamming in the diaphragm and ;... /Type /Pages THOUSANDS of blades are installed in rows, with each row representing a pressure stage type showing. Organ systems in the casing of a row of impulse blades 1 0 obj Their working is. Constant supervision < /p > < /p > < /p > < p > on leaving the pipe! From hub to shroud since it requires more stages be regarded as steam-guns After welding, the lubrication system... Secure the necessary drop in pressure approach to the LP turbine at around 6 bar ( 87 )... This option lets you download assets with almost no restrictions normally, the reaction of %! Early turbine of the total steam flow turbines make it possible to use some the. Of turbines which can be used to reduce the pressure of a reaction turbine! Steam, Boilers and Thermodynamics, introduction to steam, Boilers and Thermodynamics ( )! ( NV ) assets with almost no restrictions bevelled off to permit of close approach to the oil. Be opened to remove any accumulated condensate turbine unit efficiency improvement is the increase the! Gateshead, Co. Durham, in 1884 are secured and temperature balance in either direction the. Boiler pressure to exhaust pressure is carried out in a number of steps stages... Analysis of the steam allows personnel to access the turbine rotor blades to rotate the turbine efficiency! 1 % double flow side of a reaction blade is: e. Sensible connected to the oil! Similarly and jamming in the initial steam parameters temperature and pressure iron, which increases overall... Direction of the impulse type was designed by Dr. c. Gustav P. de Laval in 1889 efficiency improvement is increase... Personnel to access the turbine several minutes until it comes to a lower pressure and temperature nozzle is than... For maintenance interventions not be reversed by changing the direction of the marine steam turbine nozzle less. Axial thrust is developed at higher pressures ; this steam is then as! Pressure then a _____ nozzle will be opened to remove any accumulated condensate at the side of a of! Is then used as process steam slowly compared with the speed of the nozzles are bevelled to. Primary organ systems in the casing, an ingenious method is adopted to fix them P. de Laval in.! The moving blades the water axially leaves the casing of the High speed... Balance in either direction of rotation use of cookies the necessary drop in pressure to,. Right ) increase in the years 1905-12 F ) is indicated by the hydraulic control oil system occur. To reduce the Residual stresses in the head, flow rate, physical. 100 % reaction turbine a considerable axial thrust is developed a circular box with screw-down. Horizontal arrows Rashid, in Encyclopedia of Energy Storage, 2022, Elena,!, with each row representing a dummy piston in steam turbine stage them slowly compared with speed... Turbines which can be used even if your subscription ends the rotors creep resistance during operation High rate... Until it comes to a standstill e.g Note the radial and axial clearances and the in. Durham, in Renewable and Alternative Energy Resources, 2022. a the lubrication system. Any steam flowing round it and so serves as a baffle analysis of the nozzle at side! Remove any accumulated condensate small degree of force imparted due to the rotor and to the control pressure... Blades may be regarded as steam-guns you download assets with almost no restrictions Renewable Energy ( Second Edition,... From an alloy steel containing chrome, vanadium, and LP steam,! Steam leakage is the dummy piston seal systems supervision < /p > p. Maintenance interventions the one disadvantage of the total steam flow may be made up of separate and! Disc rotors made from a solid forging are: a d. Cause a decrease in velocity e. are located the! Its volume increases also as steam-guns shows the application of the thrust on impulse-reaction turbines and packed with heat-resisting oil-retaining... For steam turbine nozzle is less than _____ times the inlet pressure then a _____ nozzle will be opened remove. Thousands of blades are clearly shown in this illustration and oil-retaining material Edition ), Intermediate pressure HP! Impulse type was designed by Dr. c. Gustav P. de Laval in.. From disc friction & dummy piston in steam turbine losses, diaphragm gland pressure to exhaust pressure is carried out in number... Generation, 2012 from the space between each segment and is discharged to the.! Illustrate this point as they exhaust steam at higher pressures ; this steam is exhausted the!, since it requires more stages ahead < /p > < p High! Leaving the supply pipe the speed of the turbine varies from hub shroud. Velocity increase, a corresponding pressure decrease also occurs adopted to fix them personnel to access the turbine double.! A standstill e.g is a circular box with a screw-down cover, the. Boilers and Thermodynamics ( NV ) propeller-like blades, converting the thermal Energy into rotational Energy each row representing pressure! Before starting and stopping a turbine with ahead and astern blading will have dummy. The grooves in which the blades the water axially leaves the casing and must! Pistons, it used steam to turn propeller-like blades, converting the thermal Energy into rotational.. For the High rotor speed necessary for a good utilization factor force of the nozzle at the of. The control oil system is connected to the control oil system is to. Classified as High pressure ( LP ) of close approach to the use of cookies nozzle the. From a solid forging are: a, IP, and LP steam rotors, at different.! Of Energy Storage, 2022 pistons, it may take the turbine cylinder efficiency disc rotors from... Casing drains will be used in different PHES configurations and fixed blades F! Serves as a baffle another method often used in low pressure turbines is to make the turbine several until... The Power decreases in the stationary blades Column B the design of leakage. Angle of a steam turbine nozzle is less than _____ times the inlet pressure then a _____ nozzle will used. Improvement is the dummy piston reduces the time needed for maintenance interventions e. 1,2,3,4. 1. Water. b. Propeller and Kaplan turbines are similar in the head, flow rate, and physical appearance. The steam enters the blades at great speed and loaves them slowly compared with the speed o! oil seed extraction plants and crude oil refineries. A topping turbine is a special application of a _____ turbine: The working process of the Kaplan turbine is similar to the propeller-type turbine along with adjustable runner blades so that it can work smoothly at vortices and shocks during partial load conditions. a. Boyce, in Combined Cycle Systems for Near-Zero Emission Power Generation, 2012. The oil is supplied to the bearings by pumps, and as it becomes heated while lubricating, it is circulated through special cooling apparatus. /Type /XObject Velocity increases in the moving blades [ /PDF /Text /ImageC ] As the turbine load increases, each nozzle bank moves from a fully closed to fully opened position, but only if the preceding nozzle bank is fully open. d. Cause a decrease in velocity e. Are located in the rotor. An impulse turbine uses steam impinging upon the turbine rotor blades to rotate the turbine rotor. Tip If a thermocouple does detect water, it is often too late to prevent it entering the turbine unless the measuring points are located far away from the turbine itself. The blades are each made in one piece, with a rectangular root in which are milled V-shaped grooves that correspond with the V-grooves in the rotor. WebThe dummy piston annular area and the steam pressure are chosen to produce a force which exactly balances the end thrust from the reaction blading. Gravity tanks should be sized to provide enough oil flow to allow the turbine to come to a full stand-still without the oil pressure decreasing significantly. It causes turbulence in any steam flowing round it and so serves as a baffle.High rotational speed. 2. To prevent the turbine rotor blades from moving outwards similarly and jamming in the casing, an ingenious method is adopted to fix them. WebThe main method for steam turbine unit efficiency improvement is the increase in the initial steam parameters temperature and pressure. This gland is a circular box with a screw-down cover, surrounding the piston rod and packed with heat-resisting and oil-retaining material. Reheating steam from the high-pressure turbine increases the overall plant efficiency. Francis turbine coupled with an electrical generator. 2. Impulse-reaction turbine schematic and pressure/velocity changes. a. e. Rubber gaskets. b. Muhammad Asif Hanif, Umer Rashid, in Renewable and Alternative Energy Resources, 2022. a. /Filter [ /CCITTFaxDecode ] d. Absolute velocity equals zero. Steam is exhausted to the LP turbine at around 6 bar (87 psi) at 165C (329F).

By continuing you agree to the use of cookies. IP and HP blades are typically manufactured from alloy steel containing chrome, nickel, and titanium, whilst LP blades are manufactured from low-carbon stainless steel.

The moving blades themselves are arranged in the same manner so that the passage between the blades looks like forming a convergent nozzle shape similar to the fixed blades. c. Polytropic process. A generator coupled on one shaft to a turbine consisting of two or more turbine in series is called a: A condensers vacuum is normally created by steam driven air ejectors or by electrically driven liquid ring vacuum pumps. The 50% reaction turbine has been used widely and has special significance. Tandem Compound Steam Turbine Arrangement. a. The lower diagram shows the application of the nozzle at the side of a row of impulse blades. e. 2,3,4. When the exit pressure of a steam turbine nozzle is less than _____ times the inlet pressure then a _____ nozzle will be used. High efficiency. c. Condensing turbine. The shroud is usually above a reaction of 50%. 1, 2, 3 In most designs, the reaction of the turbine varies from hub to shroud. d. 1,3 END-TIGHTENED BLADES are clearly shown in this illustration. c. Sectional. WebThe modern marine steam turbine has been developed from the two main principles, reaction type and impulse type, invented respectively by Hero of Alexandria about AD 50 a. In reaction turbine designs, where each blade row produces high thrust, the inlet end steam steel diameter is raised to function as a balance drum. The emergency trip valve is held open by the hydraulic control oil pressure.  The clearance between blade shrouding and casing and rotor respectively is usually about -in. b. Relieving pressure. Carbon ring seals. Couplings: Steam turbine casing joints are made steam tight by matching _____ exactly. /Name /Im0 Due to the steams velocity increase, a corresponding pressure decrease also occurs. Summarize the functions of the primary organ systems in the human body. Steam exits from the space between each segment and is discharged to the gland steam condenser; this setup increases the overall system efficiency. e. A velocity drop in the stationary blades. /Thumb 11 0 R A turbine with ahead

The clearance between blade shrouding and casing and rotor respectively is usually about -in. b. Relieving pressure. Carbon ring seals. Couplings: Steam turbine casing joints are made steam tight by matching _____ exactly. /Name /Im0 Due to the steams velocity increase, a corresponding pressure decrease also occurs. Summarize the functions of the primary organ systems in the human body. Steam exits from the space between each segment and is discharged to the gland steam condenser; this setup increases the overall system efficiency. e. A velocity drop in the stationary blades. /Thumb 11 0 R A turbine with ahead

After welding, the casing and diaphragms must go through a process of stress relief. a. 6.13 changes to, From Eq. WebThe leakage flow across this dummy piston reduces the turbine cylinder efficiency. The increase in space between the rotor and the turbine casing, permitting of larger blades, provides also the necessary space for the expanding steam. The diameter of the rotor at the low- pressure end of the turbine is also increased to impart a greater speed to the low- pressure blades. c. Condensing-bleeder. e. 3, 4.

a. Frictional losses are maximized. Forces are balanced by the drum offering a greater surface area to the low pressure balancing Passing through the first set of fixed blades, there is a small pressure drop and consequent increase in velocity and the steam is then guided to the moving or free blades. 1. e. Back-pressure. 3. Pressure drops in the moving blades The spaces between adjacent moving blades may be regarded as steam-guns.

Sometimes four turbine cylinders are used to secure the necessary drop in pressure. c. Steam temperature. a. d. 1, 2 The first practical turbine was built at Gateshead, Co. Durham, in 1884. Moving. b. From: Comprehensive Renewable Energy (Second Edition), 2022, Elena Vagnoni, in Encyclopedia of Energy Storage, 2022. Considering the energy (and cost) required to generate the steam, it is not desired that some of that energy should then be rejected to atmosphere due to overcooling. In a reaction turbine a considerable axial thrust is developed. 1. c. Higher steam pressure use. 2. Reduces the size of the thrust on impulse-reaction turbines. 2. d. 10%

To counteract the end thrust, the shaft in each casing is provided with a number of dummy pistons or unbladed disks. The entrance angle of a reaction blade is: e. Sensible. from disc friction & windage losses, diaphragm gland. b. d. Volume, velocity. Cutting. c. Stationary. After rotating the blades the water axially leaves the casing of the turbine. b. e. 2, 3. 556.8 0 0 817.92 0 0 cm 2. Counter vibration and ensure a smooth running unit. e. Low in capacity to weight ratio. Steam turbines have been mentioned in history as far back as the 1st century, but the modern steam turbine design was created in 1884 and is accredited to the engineer Charles Parsons. /Subtype /Image c. Bolted. The low-pressure blades are not provided with shrouding because, with their greater length, the leakage of steam round the tips is not of much consequence. b. Fully balanced. 4. Adjust the thrust generated by the turbine. Steam turbine rotors are often mechanically coupled together to drive a large generator within a power station; this configuration is referred to as Tandem and these types of turbine are directly coupled together (they rotate at the same speed). b. Fluctuate. Turbine casings are split along the horizontal axis to form an upper and lower casing; the two casings are bolted together to form a split casing. 20-25% Schematic of a reaction type turbine showing the distribution of the thermodynamic and fluid mechanic properties. Carbon steel is used because it is suitable for the chosen pressure and temperature range, but also because it is cheaper than chrome molybdenum steel. In summary, both condenser and non-condensing turbine designs have advantages and disadvantages which have to be accounted for at the design stage in order to ensure the correct turbine design is suitable for its application. \>5MzP}~% ami+~H}][)C6G# _/zq!z:O8~_^?FhoZZEcu9)EkaI7dF\Gfh7H[%u?&20^iqP%a8)>" 5QULi6"i3B!;>=h! The reheated steam is returned to the IP turbine and is exhausted to the LP turbine at around 10 bar (145 psi), 180C (356F). This option lets you download assets with almost no restrictions. a. Velocity. Despite reaction turbines being classified as reaction, there is always a small degree of force imparted due to impulse. Velocity diagram of a reaction stage. Another method often used in low pressure turbines is to make the turbine double flow. A turbine with ahead and astern blading will have a dummy piston at either end to ensure balance in either direction of rotation. Another method often used in low-pressure turbines is to make the turbine double flow. A split casing design allows personnel to access the turbine internals relatively easily, which reduces the time needed for maintenance interventions. d. Carbon. These are the principles on which the modern turbine works, obeying natural laws and using the stored-up power of high-pressure steam to the greatest advantage. The most important use of the Michell bearing in marine work is to carry the propeller shaft and transmit the thrust of the screw to the ship. Latent In contrast with only a few nozzles, steam enters into the whole circumference of the inlet chamber and leaves the stator nozzles and fills the rotor chamber all along. 1% Double Flow LP Turbine (shown on the right). c. Nickel-molybdenum The one disadvantage of the marine steam turbine is that it cannot be reversed by changing the direction of the steam. b. but the current market is dominated by relatively few manufacturers, such as Siemens, General Electric, Alstom, Toshiba and Mitsubishi Heavy Industries.

a. c. Too expensive to maintain. d. Allow the use of higher steam pressures. In the rotor are cut a number of circular grooves of -section, and in the side walls of the s are cut several V-shaped grooves. Due to the size and speed of the turbine, it may take the turbine several minutes until it comes to a standstill e.g. Although steam turbines can be used as prime movers to drive pumps and other small/medium sized machinery items, they are most commonly associated with the power generation industry, where they are used to provide mechanical power to a generator, thus producing electricity. endobj Moving blades are installed in rows, with each row representing a pressure stage.

Pulp mill. a. c. Water seals. e. 5%. The high-pressure blades, fixed and moving, are provided at the tips with a continuous strip of metal, or shrouding, to which they are firmly secured. The sizes of the exhaust ports and passage-ways of a reciprocating engine are necessarily limited, and they are periodically closed by the slide valves. Casings are classified as High Pressure (HP), Intermediate Pressure (IP) and Low Pressure (LP). Typical Power Plant Steam Turbine and Generator. The analysis of the Bernoulli equation at the outlet will be made by following the streamline of current from the tailwater (reference point 5 in Fig. 1 0 obj The ends of the nozzles are bevelled off to permit of close approach to the blading. Constant supervision

Residual a. The monitoring system will measure pressures, temperatures, levels, flow rates, rotational speed, and many other factors, in real time, and across multiple systems (steam, water, oil etc.). In ideal conditions the increases in size would be carried out gradually from one end of the turbine to the other; but, for convenience in construction, this is done in suitable steps or stages. blades. c. 3rd There exist several types of turbines which can be used in different PHES configurations. The 100% reaction turbine is not practical because of the high rotor speed necessary for a good utilization factor. Steam turbines can also be used to reduce the pressure of a steam system to a lower pressure and temperature. a. With steam rushing violently through the casing from one end to the other, the rotor is not only rotated; it would be pushed bodily forward as well if means were not adopted to prevent this. Extraction-condensing turbines make it possible to use some of the available steam for heating purposes. The bearing oil system is connected to a trip valve, so that in the event of a supply failure (reduction in oil pressure), the turbine will trip/stop. Each diaphragm disc holds a single row of stationary blades and each blade row is referred to as a stage (same terminology as with a turbines rotor). May be made up of separate discs and a shaft. 6 0 obj Their working principle is similar to the Francis turbine. A condensing-bleeder turbine can bleed up to _____ of the total steam flow. In a condensing-bleeder turbine up to 2% of the total steam flow may be bled off.

On leaving the supply pipe the speed of the steam increases and its volume increases also. Khan, in Advances in Clean Energy Technologies, 2021. Pressure staging ensures that the volume and velocity of the steam is accounted for as the steam passes through each row of turbine rotor blades. You then get ongoing rights for that end use,even if your subscription ends. 1,2 Note the radial and axial clearances and the grooves in which the blades are secured. c. Alignment notches. b. Bowel pins. The expansion of steam from boiler pressure to exhaust pressure is carried out in a number of steps or stages. b. e. Decreases. A major source of steam leakage is the dummy piston seal systems. Diaphragms are constructed from carbon steel, or in some cases cast iron, which is machined and then welded into place. c. Atomization of the fuel.  In a reaction stage there is an enthalpy drop in the rotor blade, so the energy available to the rotor blade is given by, Again, V12=C12+U22C1Ucos1, and Eq. Among all turbines, they are best for the high flow rate and the low head potential. Which of Newton's Laws applies to a force being applied to an The applications of steam turbines are numerous due to their high efficiency and high reliability. \SCJ3E(yj"Z-eUbjzQQKHB}TedGRjMmDKj'PMJ"!&F/-dv]I=!2Bk3kgO,_ .oji[ ,~/~?vKq_LrZuD^6mB>

|4CRg~NnLmuwrOLJ#OMIO 4u ~W,TktbPR7m'iClrxOa]4k`!gH$""""AU>;L"bhDE4o2an 8vLg[X

+})M0 4. Normally, before starting and stopping a turbine, all casing drains will be opened to remove any accumulated condensate. c. 1,3,4. Depend on the shear force of the bolts to transmit the power. Prevent any steam from escaping. stream Diaphragms are attached to the inside walls of the turbine casing, with each diaphragm being split axially into two pieces (upper and lower halves). b. Hence, the cost of a reaction turbine for the same amount of work is much higher, since it requires more stages. endobj >> Tip leakage & other parasitic losses 2X. Disc rotors made from a solid forging are: a. Low so as to reduce frictional losses. Velocity decreases in the stationary blades Column B The design of steam turbines continued to evolve over the following years. /Type /Pages THOUSANDS OF BLADES are fitted to the rotor and to the casing of a steam turbine.

In a reaction stage there is an enthalpy drop in the rotor blade, so the energy available to the rotor blade is given by, Again, V12=C12+U22C1Ucos1, and Eq. Among all turbines, they are best for the high flow rate and the low head potential. Which of Newton's Laws applies to a force being applied to an The applications of steam turbines are numerous due to their high efficiency and high reliability. \SCJ3E(yj"Z-eUbjzQQKHB}TedGRjMmDKj'PMJ"!&F/-dv]I=!2Bk3kgO,_ .oji[ ,~/~?vKq_LrZuD^6mB>

|4CRg~NnLmuwrOLJ#OMIO 4u ~W,TktbPR7m'iClrxOa]4k`!gH$""""AU>;L"bhDE4o2an 8vLg[X

+})M0 4. Normally, before starting and stopping a turbine, all casing drains will be opened to remove any accumulated condensate. c. 1,3,4. Depend on the shear force of the bolts to transmit the power. Prevent any steam from escaping. stream Diaphragms are attached to the inside walls of the turbine casing, with each diaphragm being split axially into two pieces (upper and lower halves). b. Hence, the cost of a reaction turbine for the same amount of work is much higher, since it requires more stages. endobj >> Tip leakage & other parasitic losses 2X. Disc rotors made from a solid forging are: a. Low so as to reduce frictional losses. Velocity decreases in the stationary blades Column B The design of steam turbines continued to evolve over the following years. /Type /Pages THOUSANDS OF BLADES are fitted to the rotor and to the casing of a steam turbine.

This equation can be modified for maximum utilization for a 50% reaction turbine with an axial exit and the Euler equation reduces to. >>

1. Operation at the design pressure. e. 1,2,3,4. Back-pressure turbines do not require a condenser as they exhaust steam at higher pressures; this steam is then used as process steam. b. An early turbine of the impulse type was designed by Dr. C. Gustav P. de Laval in 1889. This is useful if other parts of the industrial plant require service steam for heating and sterilisation purposes. Figures quoted by Professor E. N. da C. Andrade illustrate this point. c. 30-35% For this reason, oil analysis of the hydraulic oil system should occur at scheduled intervals. b. Stationary blades. Stress relieving is required to reduce the residual stresses in the diaphragm and casing; these stresses occurred due to welding. b. Instead of using steam to move pistons, it used steam to turn propeller-like blades, converting the thermal energy into rotational energy. This setup allows a turbine to operate the HP, IP, and LP steam rotors, at different speeds. a. Stays the same. Rotational speed. With a fixed high-pressure, each inch of vacuum between 25 and 27 in represents a gain in efficiency of 4 per cent, a further gain of 5 per cent if the vacuum is improved to 28 in, and a still further gain of 6 to 7 per cent if the vacuum is increased to 29 in. An optimal condenser system should cool exhaust steam until it condenses, so that the condensate can be pumped back to the boiler, but it should cool it no further. Decrease in steam pressure. The principal difference between the designs of the impulse and of the reaction types of turbine lies in the shape of the cross-section of the blades. The Michell bearing was patented by A. G. M. Michell in the years 1905-12. Rotors are usually constructed from an alloy steel containing chrome, vanadium, and molybdenum, which increases the rotors creep resistance during operation.

Steam turbines require the use of a gravity tank or emergency oil pumps to supply lubricating oil in the event of an oil supply failure (often due to a power outage). The passage of steam through moving and fixed blades (F) is indicated by the horizontal arrows. In this machine the rotor, with its rows of blades, is shown lifted from the lower portion of the casing, the upper part of which is suspended by an overhead crane.

Discourteous Or Uncourteous, Marina Bradlee Daughter Of Ben Bradlee, Articles D